Advanced Technologies: OCR imaging setup performs license plate verification

14.09.2012 - Advanced Technologies: OCR imaging setup performs license plate verification. Border crossings, secure areas, parking facilities, and even highway speed traps are all places where ...

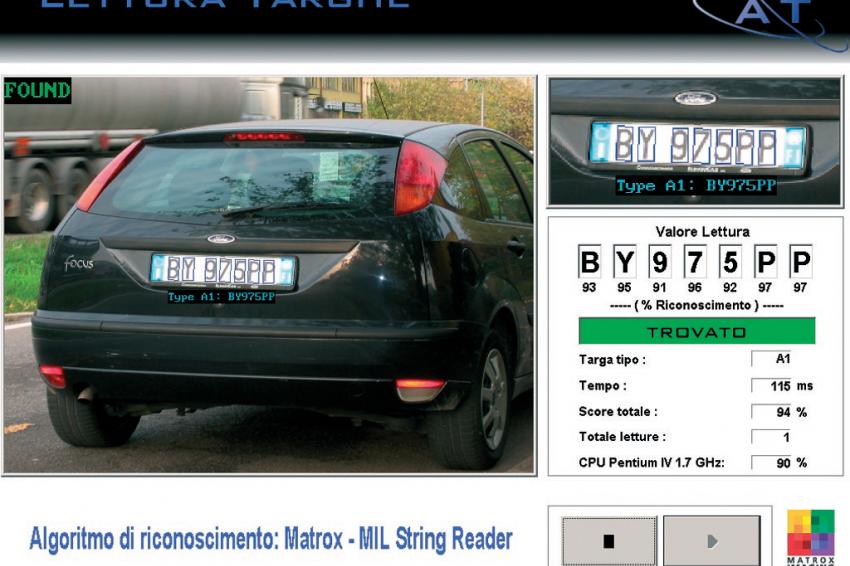

Advanced Technologies: OCR imaging setup performs license plate verification. Border crossings, secure areas, parking facilities, and even highway speed traps are all places where license plates on cars are captured by imaging devices. In Italy a hightech license plate reader is used by an intelligence service, where the license plate is read, the information is sent to a database, and then the truck or automobile is allowed to proceed into a secure area.

Advanced Technologies and Sinartis of Milan, Italy, took on the task of designing and installing this intelligence system in just six months. License plate reading applications are in use in many places around the world, but Advanced Technologies had several requirements for this project. The first requirement was to be capable of high-quality imaging in a real environment.

According to Davide Nardelli, managing director of Advanced Technologies, the lighting situation can be complex. “The sun could be on the front or back of vehicle, it could be completely bright or completely dark.” Another requirement was that the license plate reader work regardless of what it’s attached to or what its vantage point is. For example, it could be attached to a moving gate, a fixed pole, and could be exposed to the elements or somewhat shaded.

Another basic requirement was for the system to quickly capture the plate number and send it to a centralized database by a wireless network, while simultaneously compressing and saving the image locally so it could be downloaded offline. The system chosen for the task integrates several technologies including radar, a Basler A102k 1.3 megapixel Camera Link camera, a Matrox 4Sight-II industrial vision computer and a lighting device. The radar locates the moving vehicle, which triggers the lighting and the camera.

The light, which is LED-based, is flashed, and the image is captured. Image acquisition, processing and display is done with the Matrox 4Sight-II equipped with a Matrox Meteor-II/ Camera Link for PC/104-Plus frame grabber. Nardelli explained that they chose Matrox Imaging Library’s String Reader software, an opticalcharacter recognition (OCR) tool, because it’s able to handle extreme contrast variations, such as from daylight to nighttime, and geometric distortions.

The application also uses Matrox Imaging Library’s compression/decompression module. Matrox Imaging Library’s JPEG compression algorithm is highly optimized and compresses images much faster than third-party compression software. The vision hardware and software is housed in the Matrox 4Sight-II so it’s protected from harsh environments. The radar and lighting system are perfectly synchronized to ensure that the license plate is in the correct field of view and properly lit so that the software can read it.

The Hardware/Software Combo

The vision components of the system include hardware and software. On the hardware side, the Matrox 4Sight-II industrial computer offers desktop PC performance in a compact, rugged enclosure. Image capture, processing, display, networking and general purpose I/O are integrated into a single unit. It includes an embedded Intel Celeron or Pentium III processor and offers support for standard and non-standard analog and digital video acquisition including Camera Link.

In this application, Matrox Meteor- II/Camera Link for PC/104-Plus frame grabber is capturing the video. The 4Sight-II is programmed using Microsoft development tools and Matrox Imaging Library. The difference between using the Matrox computer as opposed to an off-the-shelf system is that with Matrox, a single vendor integrates all the components, so compatibility is ensured. This dramatically reduced the amount of time that Advanced Technologies had to spend ensuring component interoperability, not only during development but also when the license plate application was put into use.

Other advantages to the Matrox integrated system are its small size because it can fit into spaces that wouldn’t accommodate a traditional-PC based vision system, and its rugged enclosure allows it to handle most industrial environments. On the software side, it was important to Advanced Technologies to use off-the-shelf software. Only in this way could they keep costs down, and ensure that the system would be portable without requiring new calibration when installed on a new light pole or parking lot gate.

The OCR software module, String Reader, offers a common programming interface that is compatible with Matrox hardware such as frame grabbers, vision processors, stand-alone systems and smart cameras.

Meeting The Requirements

One of the requirements of the application was the ability to perform the recognition and compression quickly, and the result was that the setup could perform plate recognition and image compression on high-resolution images (1300 x 1024) in less than 500 milliseconds. This is the minimum requirement “to ensure that we don’t lose any cars or trucks, traveling at reasonable speeds,” according to Nardelli. The application designers determined that the minimum CPU speed necessary to process all tasks was 1GHz.

In addition to the technology integration, the intelligence service seeking the system was looking for something with an open programmable environment with the right flexibility for customization. By working with Matrox, this application helped drive the research and development of Matrox Imaging’s feature-based OCR software. This level of programmability is now included in the MIL String Reader module.

Anne L. Fischer

Reprinted with permission from the February 2005 issue of Photonics Spectra.

Contact:

Advanced Technologies S.r.l.,

Trezzano sul Naviglio/Milano, Italy

Tel.: + 39 02 4455 154

Fax: + 39 02 4453 103

infocom@adv-tech.it

Matrox Imaging,

Dorval, Quebec; Canada

Tel.: +1 800 804 6243 or 514 685 2630

Fax: +1 514 822 6273

imaging.info@matrox.com

www.matroximaging.com