Power to the People

A Multilayered Approach to Power Plant Safety

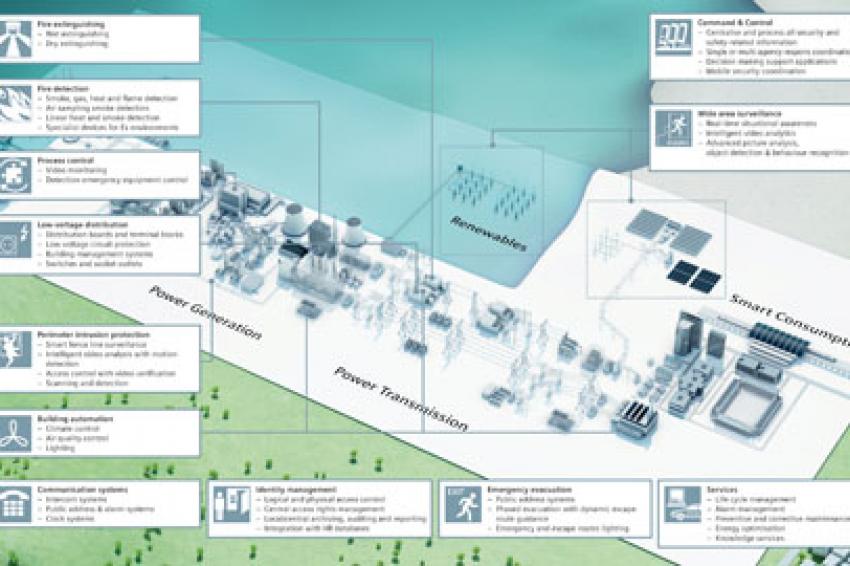

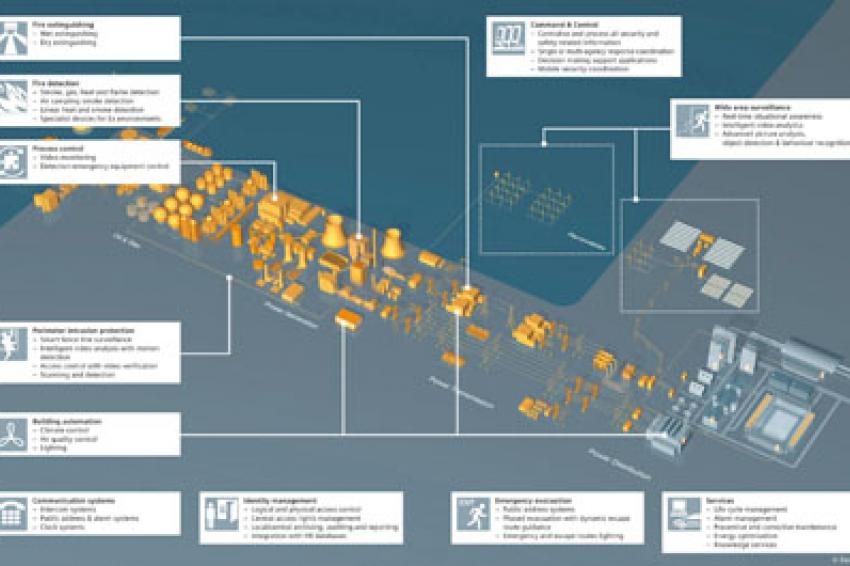

Coal, gas, nuclear or hydro-power, solar power, geothermal, renewable energy, combined cycle or biomass - every power plant is different. From the way in which it produces energy, its location, its design, age and time of commissioning, national legislation and local regulations to regional fire departmental regulations and even insurance stipulations; all need to be recognized as factors which influence the demands of each site for security, fire safety and building comfort.

Horst Köhler, Head of Utilities Solutions at Siemens Building Technologies Division, has examined the benefits of an integrated approach to danger management in protecting the continuity of power supply. All these different types of generation are similar in that their commercial success depends on the capability to manage operational risks and to provide continuity of supply. Given that a power plant plays such a fundamental and critical role in a country's infrastructure, supply disruption can have significant effect - both economical and political - with even short-term interruptions leading to inconvenience on a massive scale, price increases and/or rationing for the areas supplied.

Supply Reliability

Power facilities carry many inherent operational, security and fire risks that threaten their daily operations, from theft, vandalism and equipment failure to fires and leakage of potentially hazardous materials. And various political situations around the world, along with the volatility of energy prices, are provoking a new wave of terrorist threat. Safeguarding power facilities against the diversity of internal and external threats calls for an integrated risk management strategy, with integrated solutions in security, fire safety, electrical installation and building automation.

An effective safety and security system needs to be modular, scalable and adaptable in order to cope with changing requirements. The risks and threats facing any power plant can include major events resulting from a terrorist attack, fire, industrial accident, arson, malicious damage or sabotage to normal ‘everyday' problems such as trespassing or political activists, vandalism, internal theft, data theft, leaking of hazardous materials etc.

Such a system also needs to cater for large numbers of staff, visitors and contractors, as well as multiple buildings that, on a power plant, can often be far apart. Critical functionality includes the flexibility to be able to set or unset alarms locally whilst allowing for central monitoring, the ease of identification of the origin of an alarm and reliable alarm verification to ensure an adequate and appropriate response.

From the Outside Inwards

A ‘multi-layered' safety and security strategy, which involves a range of systems and capabilities - both physical and electronic - is the best way to keep the sites of our power plants safe and as secure as possible, from the perimeter fence to the turbine room. External fences or walls are the first line of defense against unauthorized intrusion, so the monitoring and surveillance of perimeters is therefore vital for large and complex sites such as power plants. External motion detectors have an important role to play in a multiple-layered approach to plant security. Systems offer versatile alarm transmission methods, as well as the capability to integrate with danger management stations and video surveillance systems.

When used in combination with video surveillance, external detectors can offer proven reliability and high effectiveness in pro-active surveillance, even in harsh, fast-changing environments. They can support remote maintenance and alarm status verification for cost-effective monitoring and speed of intervention. They will normally trigger an alarm as soon as intruders set foot in restricted areas, allowing for real-time verification and response before access to critical areas has been gained. Intelligent alarm verification processes also ensure a high detection accuracy and unparalleled false alarm immunity.

Patrolling and Video Surveillance of Outer Areas

Sites such as power plants are usually large and complex with an extended perimeter. Ensuring their integrity can require a large number of security staff, either patrolling the site or watching images and data transmitted by a large number of surveillance cameras and other alarming/sensor devices. Research has shown that observers find it impossible to concentrate sufficiently or for long periods of time to monitor even a modest number of video screens efficiently, let alone the large number needed to cover the surveillance systems of extensive sites.

Integrated intelligent video security solutions, based on a combination of risk-appropriate protective measures, can assist in the protection of life, assets and critical infrastructure with accuracy, reliability and short response times. Video sensory analysis, technology able to gather and filter available data to an extent that a single operator can handle and manage all available information without fatigue, allows security personnel to focus on critical situations. It supports their decision-making by providing the critical information required to detect, manage and prevent potential security breaches in real time. Efficiency of the system can be further enhanced by policy-based alarming, object identification, automatic flagging and preventive risk indication.

Secure and Authorized Access to Buildings and Offices

With the perimeter patrolled by guarding staff for out of hours or in high risk plants, fences electronically monitored and external areas filmed by surveillance cameras for attempted break-ins and other potential problems, outbuildings and storage areas are the next level needing protection.

Provided these areas around the site are secured with strong defenses and reliable locks, electronic systems can provide secure and authorized access. These access control systems ensure that only people with pre-arranged clearance are given physical access to controlled buildings, rooms and offices within the site. And, more importantly, that unauthorized people are kept out.

Fully integrated access control systems can provide high levels of security and convenience at the same time, offering freedom of movement in a secure environment for workers, management, contractors and visitors alike. From outbuildings to offices, they enable entry to the many restricted areas in power plants (including access to sensitive computer data and systems), to be controlled at all times. They allow staff or visitors to be issued with an access card that determines areas to which they can gain access - and the times at which they can do so. Plants running multiple satellite buildings benefit from central management of access rights, allowing staff to access any building with a single card. The same card can be used for realizing a ‘Time & Attendance' solution, checking employees in and out and registering their hours.

Open systems architectures again allow the surveillance systems to link to other electronic equipment such as access control and intruder detection solutions, interworking with other security and building management functionality e.g. video surveillance, fire safety, intruder detection or management stations for added flexibility and control over the site‘s management.

With the advance in technologies, video surveillance can be set to record on alarms generated at an access control point (in case of forced entry for example) and video cameras and recordings can be accessed and managed remotely over the network from a central control room. Access rights are managed via a central database, and can be tailored to suit the access requirements of each member of staff, based upon seniority or working hours. Doors are permanently locked unless a legitimate user presents an authorized card to a reader at the door, or enters the correct code. Biometric technologies (fingerprint, 3D face recognition systems, iris scanning etc.) can be integrated to reach an even higher security level for special areas.

Control of Office Building Systems

The offices and buildings on power plants are becoming increasingly complex and differ in many ways: use, size, operating hours, central heating, air conditioning or changing occupancy requirements and environmental conditions. But automation systems do not just control the basics. With appropriate system tailoring during planning, installation and commissioning, they are able to integrate common open protocol devices into a single, robust control system. They regulate airflow, monitor energy use and can now be called upon to integrate with security, lighting and other systems throughout buildings to deliver comfort, safety and energy efficiency. And automation can make office comfort and security systems easier to manage and operate - controlling everything through a single workstation with remote access from anywhere via secure networking technology.

Protection of Power Plant Processes and Personnel

Customized security solutions for all different plant types - and their possible future development - ensure rapid detection, fast and adequate reaction, and help to trigger the appropriate response against all type of incident. With wide-scale video surveillance of process areas and all other sensitive places, real-time verification of incidents can take place immediately an alarm has been triggered either by a detector or a member of staff. This helps to protect personnel and assets, as well as improving operational efficiency and recovery times, while reducing costs and downtime.

Protection against fire, heat and smoke naturally plays a key role in ensuring power plant safety, especially in problem areas like turbine halls and cable trays. Intelligent fire protection solutions offer the latest systems for the detection of fire, smoke and heat in even the very earliest stages of combustion, tailoring detection to each specific area or environment, to spot dangers as soon as they occur before they have the potential to escalate. But if, through unavoidable circumstances they do and a fire takes hold within the plant, various extinguishing methods are available depending on its location, including foam deluge systems and gaseous extinguishing systems.

Danger Management of the Whole Site

The growing need for plant security brings new solutions, systems and processes that facilitate the free, safe and efficient movement of people, commodities and information. Today more than ever, with the risks and threats that exist, making security decisions is not an easy thing to do. And providing a plant safety and security solution that integrates different systems into one comprehensive administrative entity is not just about merging equipment, systems and technology. It is about putting into practice a design concept to support normal working life and business operations whilst ensuring fast and efficient response to emergency situations. Importantly, post incident reporting analysis - a regulatory requirement - provides data analysis should an incident occur, enabling the necessary procedures to be put in place to help prevent it happening again or to have a robust response if it does.

In conclusion, it is important to recognize that the requirements of no two power plants are identical. Appreciating those differences is crucial in establishing an integrated solution which truly safeguards energy provision, from power generation on to transmission and through to distribution. With the world focusing more than ever before on providing continuous energy supply and the means through which we can now meet the rising demand, protecting the infrastructure and reliability of supply has reached its highest ever level of importance.