Gas Detection: Finding Hidden Savings During Challenging Economic Times

29.05.2012 - During economic downturns, every department is asked to save money to weather the storm until economic conditions improve. Personal Protective Equipment (PPE) departments are not u...

During economic downturns, every department is asked to save money to weather the storm until economic conditions improve. Personal Protective Equipment (PPE) departments are not usually exempt from cost-cutting measures. This article offers guidance regarding where to find savings within your gas detection instrument fleet without compromising safety or instrument performance.

The current financial crisis makes the job of safety and smart product purchases more difficult, as your PPE purchasing decisions could result in severe consequences. Cutting your budget may seem to be impossible, as you've turned every penny twice during the last cost-cutting round of choosing the most economical gas detectors. It's highly unlikely that a reduced number of gas detectors or new purchase delays will not produce a safety compromise!

The Best Detector

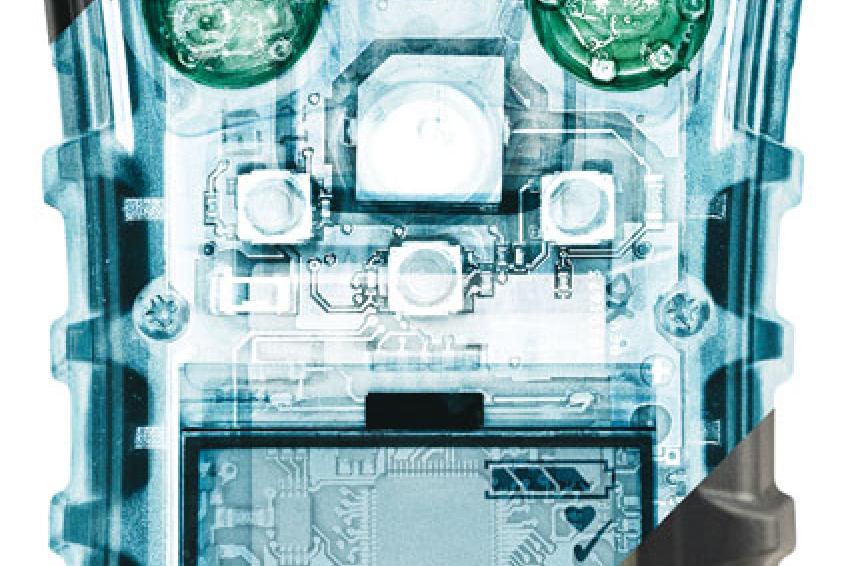

What makes one gas detector superior to another, and how can you purchase better-performing detectors and still save money? The answer lies in considering feature combinations such as battery technology, rugged instrument construction, ease of use (minimal required training), calibration and maintenance frequency, reliable software, and most importantly sensors, the core of gas detectors. A gas detector's primary task is straightforward: to detect and monitor specific gases and reliably alert users to the presence of potentially hazardous gas concentrations. Regardless of other advantageous features offered by a given instrument, without superior sensor technology, finding reliable gas detection can be challenging. Most manufacturers use off-the-shelf sensors from known sensors suppliers. Critical performance factors such as response times, cross-sensitivity, and sensor lifespan are likely to lack sensor differentiation. However, even if you're able to find best-in-class gas detectors, price tags may make you consider buying two detectors instead with lower quality and performance. To resolve this dilemma, it is necessary perform a longterm cost-of-ownership calculation using what's inside as our main driver, the gas detection sensors.

Superior Sensors

Much has been said and written about the importance of loud alarms and robust instrument construction; for simplicity's sake let's focus on how sensors impact your long-term costs. Superior sensor technology not only offers great performance, but also cost-savings while enhancing safety. How? Great sensors offer better stability within challenging environmental conditions, faster response times, and longer expected sensor life. MSA's recent innovation in sensor design technology offer improved performance by embedding electronics inside sensors.

Embedded electronics convert typical analog signals to digital output, resulting in sensor noise control, reduced spikes, decreased RF interference, and endof-sensor life forecast. Increased sensor stability means fewer false alarms and lower calibration frequency; this factor combined with end-of-sensor life forecast results in better planning and decreased down time. Superior sensor technology combined with well-designed software and instrument design enhances safety by offering more reliable performance. The actual cost of operation shutdown due to false alarms may be substantial and is often not sufficiently accounted for. So what are the tangible savings? Calculate your total costs over longer time periods as little is likely to change within the first two years; replacement components are generally covered by manufacturer warranties. Although most manufacturers offer two-year warranty, claims made within this period often have to be paid via pro-rated discounts for specific sensors or with new instruments to offset the used time within the warranty period. In addition, most manufacturers may also challenge your warranty claim's validity, citing instrument abuse or misuse. Reputable manufacturers, like MSA, typically provide replacement instruments or sensors with no questions asked.

Hidden Costs

The average lifespan of current-generation gas detectors is about four years or less, usually limited by sensor, electronics, and battery replacement costs. As an example, let's compare cost of ownership over four years, including cost of calibration gas and an average one-time sensor replacement. A fourgas diffusion gas detector costs about 650 €; replacement sensors could cost you more than the detector's initial purchase price as well as associated failure risks of other components for the following two years. So, after the first two years of warranty, it is probably more economical to purchase new detectors offering two full warranty years, leading to 1300 € total. Regulations require response tests to be done before each day's use to verify proper instrument operation; this process takes 30 up to 90 seconds, depending upon the test and manufacturer. Most manufacturers offer 0.5 lpm regulators, resulting in 0.5 lpm x 30 sec x 250 working days x four years = 250 liters of gas not including calibrations.

If a quad-gas cylinder containing 58 liters costs 280 €; you'll need (250/58) five cylinders x 280 € = 1400 €. Total cost of ownership: 1300 + 1400 = 2700 € for one four-gas detector, excluding downtime and labor costs. Next, consider MSA's regulators of 0.25 lpm and T90 response times < 10 seconds for oxygen and combustible gas, < 15 seconds for CO and H2S), and bump test times of less than 10 seconds. Using the same math, 0.25 x 10 sec x 250 x 4 = 42 liters allows us to purchase one cylinder for 280 €, a difference of 1120 € on calibration gas only!

MSA offers four-gas detectors for 900 € including four-year warranties, the result is 2700 -1180 = 1520 € in savings for one detector. These savings don't even include probable reduced downtimes due to shorter test and calibration times, labor, and reduced operational delays due to false alarms caused by lesser sensors.

Just imagine the savings for 10, or as with many larger facilities, hundreds of detectors! It really pays off to request additional details and insist upon instruments warranted for four years.

Other Areas for Savings

Newer rechargeable battery technologies such as lithium-ion have no significant memory effects, offer higher capacity, and are able to hold charge much more efficiently than previous rechargeable battery generations. Detectors can be stored for months without depleting battery charge; runtimes of up to 25 hours have been reported for four-gas detectors. Improved battery performance may eliminate the need for additional alkaline batteries, easily saving you hundreds of Euros every year. Is instrument construction rugged enough to survive rough industrial use? Is instrument housing sufficiently dust- and water-tight to help prevent damage during outdoor use? An easy-to-operate instrument minimizes training needs for your personnel. Good instrument design and construction saves you significant cost and time over the years.

Conclusion

In economic downturns when every penny must be scrutinized before spending it, consider unconventional cost-savings areas without compromising safety. Long-term cost of ownership is often not reviewed carefully and typically costs much more than initial gas detector purchases. Choosing MSA's superior sensor technology and construction reduces your overall cost of ownership while increasing instrument performance and safety with faster response to gas hazards. MSA will provide you with guaranteed cost of ownership over four years and back our claims by offering extended warranties. It's unlikely that you can change the economy, but these considerations are very likely to impact how economic conditions affect your company and your profits.

Contact

MSA Auer GmbH

Thiemannstr. 1

12059 Berlin

Germany

+49 030 6886 0