Sealing Safely

Optimal Safety Solution for Filling and Sealing Machines

Rychiger, with its head office in Steffisburg in the Bernese Oberland, belongs to the leading international manufacturers of customer-specific filling and sealing machines. Their safety is monitored by various components from the Swedish company Jokab Safety whose key products are electronic safety modules and magnetic locks with an integrated safety sensor. Various safety relays and adaptors provide contact expansion, switching delay, and time-saving wiring via M12 connectors.

The Swiss company Rychiger, founded in Steffisburg in 1918, is specialized in manufacturing filling and sealing machines for premolded aluminum or plastic containers for food, pet food, coffee and tea as well as pharmaceuticals. It has 140 employees and reaches an export rate of more than 80 %.

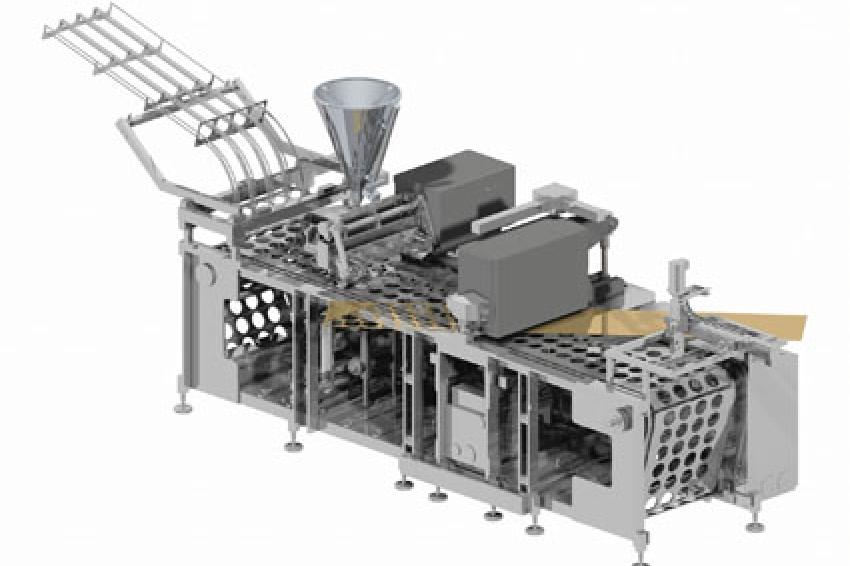

The Rychiger FS 680 machine fills and seals all kinds of premanufactured portion-packs. The modular machine, designed for wet cleaning, can be configured as required and easily adapted to the corresponding product, packaging-material, and process requirements. It is suitable for the filling of liquids, viscous and highly viscous products, lumpy goods and powdery products.

Decades of experience in heat sealing technology, innovative ideas, and close customer relations have led to the conception of a wide product range, which ranges from semi-automatic entry-level machines to complex, fully automated machines. All machines are characterized by their highly precise, repeatable sealing technology, which is based on short sealing times, a high sealing pressure and low sealing temperatures. Their unique punching technology, extremely low foil-consumption and precise fillers provide sustainably low operation costs.

Magnetic Lock with Integrated Safety Sensor

The Magne 2 magnetic lock with a built-in Eden safety sensor was developed for use in just such industrial safety applications. It can hold a door or hatch closed electrically with a force of up to 1,500 Newtons. The touch-free Eden sensor monitors that the door or hatch is securely closed. The magnet includes an information output contact which reports when the holding force has reached the level needed. This permits the supervision of correct positioning and ensures that there is nothing between the magnet and the holding plate.

Different holding forces (up to 1,500 N) can be achieved by connecting different voltages between 0V and 30V to the magnet. At 0V the magnetic field is completely gone and there is no residual magnetism, so no magnetic material will be held on the magnet, ensuring a reliable application. In conjunction with the Tina 12A junction block and the lock's 8-pole M12-connector, two locks can be easily connected to one Pluto safety PLC or to one Vital safety module. The accessories available include a mounting kit, a plastic handle and a handle profile for mounting on a hinged door with the Quick-Guard fencing system and a door gap of 5 to 15 mm.

Safety Modules and Sensors

The Vital electronic safety module which is only 22.5mm wide makes it possible to install and dynamically supervise many different types of safety devices connected in the same safety circuit and still achieve the PL e performance level according to EN ISO 13849-1. It also has automatic or manual supervised reset, dual NO safety outputs, an information output for reset indication, and status information for PLC‘s. The modules have an LED indication of power ON, presence of dynamic signals and output status. Detachable connector blocks make it easy to troubleshoot or change a module. Vital can supervise up to 30 Eden or Tina devices and the 2 outputs have a switching capacity of 6A/250Vac/1500VA/150W.

An Eden non-contact safety sensor pair is mounted on each maintenance door. It consists of the active, electrically connected part called Adam and the passive part called Eva, which acts as an actuator. A coded signal is transmitted from the Vital control device or from the Pluto safety PLC via Adam to Eva, which modifies the signal and sends it back again. The sensor is only activated, if the door is closed and Adam and Eva are face to face. Here, the wide tolerance for distance and misalignment between Adam and Eva and the blinking frequency of the LED, which serves as an alignment aid, ensure a very easy and time-saving installation. The sensor has a sensing distance of 0 to 15 mm and is maintenance and wear free. The signal can easily penetrate through non-metallic materials such as wood or plastic.

Status Information

Thanks to the unique dynamic input and output signals, it is possible to monitor up to 30 non-contact sensors with a Vital safety module or up to 150 sensors with a Pluto safety PLC using one channel. Thereby, the highest safety category 4 is maintained and an information signal indicates the state of each single door. The Tina 8A connection block is available with 8 M12-connectors. It enables several safety components having M12 connection terminated cables to be connected together. The block is connected with a suitable multi-core cable that carries status information from each safety component to the control cabinet. The connection block contains electronic circuits which modify the coded dynamic signal in the safety circuit. Several connection blocks can be connected to one Vital safety module or to one Pluto safety PLC.

The automation specialists at Rychiger, responsible for electrical engineering, value various aspects of the Magne 2 magnetic lock; its high closing force and slim shape; the high protection class IP67; the plastic housing which is appropriate for food and resistant to milk powder. They see a particular advantage of the Vital safety module in the fact that it can replace many safety relays and monitor up to 30 Eden sensors.

Compared to the previous solution with 2-channel monitoring, trouble-shooting is now much simpler and the Tina adaptors used as distributors greatly reduce the wiring costs. The Rychiger specialists are also very satisfied with the advice, the price/performance ratio, the high resistance to wetness as well as the approvals for Europe and Asia. Detailed documentation on the safety components and various circuit diagrams are available free of charge.

Contact

Jokab Safety Deutschland GmbH

Max-Planck-Straße 21

78549 Spaichingen

Germany

+49 7424 95865 0

+49 7424 95865 99

Jokab Safety AB

Boplatsgatan 3

21376 Malmö

Sweden