Everything You Need to Know on Fire Detectors

It could be so easy to see, choose and install a fire detection system or even just a fire detector. But detectors are as different as the scenarios that they need to protect. For example, if you have high ceilings, smoke must first get to that point where the detector is mounted – it costs valuable detection time. So, let’s start with explaining which detector is suitable for which scenario.

What Different Kinds of Fire Detectors Are There?

- Smoke detectors: Optical, Ionization, Dual Sensor Detector, Aspirating Smoke Detector

- Heat detectors: Thermal and thermovelocimetric detector:

- Flame detectors: IR detector (Infrared), UV detector (Ultraviolet)

- Linear infrared detectors/thermal imaging

- Video fire detectors

- Gas detectors

There are smoke detectors, heat detectors, flame detectors, linear infrared detectors/thermal imaging, video fire detectors, and gas detectors. These subcategories of detectors cover the most regularly used detectors. As one can tell only by their names, the way they detect fires functions differently. Some detect the difference in smoke particles, others use temperature or deviation in infrared light.

Smoke Detectors: What Is the Difference Between an Optical, an Ionization and a Dual Sensor Detector?

The most classical detectors are smoke detectors. They are widely used and are easiest to install. Oftentimes, many will call them “point type smoke detectors” or “point detectors” which refers to the most standard ceiling-mounted detectors.

Smoke detectors detect smoke particles in the air. As soon as the quality of air changes, they give out an alarm. That being said in an easy way, there are four kinds of smoke detectors:

1. Optical smoke detector or photoelectric detector: These kinds of detectors contain a light beam to detect smoke particles in the air (photoelectric technology). When the light is intermitted by floating particles, it triggers the alarm. They are very sensitive to smoke from a slow, smoldering fire, as they detect rather medium and large smoke particles. Therefore, it takes a bit for them to get triggered.

2. Ionization detector: The function of this detector is a bit harder to imagine. It produces ionized air. That means they create an electrical charge and a current to flow inside the detector. When smoke particles get inside, they detect a deviation in electrical charge and the alarm sounds. These kinds of detectors are very sensitive and easily triggered by changes in air (pressure, temperature, etc.) Hence, they are sensitive to fast, flaming fires and analyse smaller and medium size particles.

3. Dual sensor detector: This detector uses both ionization and photoelectric technologies in one alarm. This is why it is best for earliest possible warnings, regardless of the type of fire.

It is a tough choice to decide what kind of fire detectors are useful for each individual scenario. Sebastian Wehr, Product Manager for Fire Detectors at Bosch Building Technologies says: “One trend in the industry is certainly to use multi-sensor technology to further improve detection capabilities. We recommend the multi-sensor approach for demanding environments. Two or more sensors combined in one device can increase the false-alarm stability and, at the same time, make a system more robust.”

The Avenar detector 4000 series from Bosch is a flexible series of nine detectors for both manual and automatic addressing systems. They are available in single, dual and multi-sensor versions for specific applications and are equipped with intelligent signal processing based on more than 4,000 fire patterns to deliver highly reliable detection performance.

As you can see now, many providers today combine different functions of detectors already, because it makes the system more secure.

Another fire detection system, the Zettler Profile, a brand by Johnson Controls, comes with associated 3oTec detectors and offers very stable technology with rapid response time and less frequent nuisance disruptions, e.g. by false alarms. Flexibility and scalability of the panel and the parameterization of the addressable detectors allow quick adaptation to all customer needs.

Optical smoke detectors using the light-scattering principle are a very good compromise between cost and efficiency. Using a detector which combines smoke detection with heat detection and even CO detection reduces false alarms significantly.

4. Aspiration smoke detector (ASD): This detector per se is the same as the others. It also uses either optical or ionic detection. The difference is: It leads the air to the detector through suction pumping and through pipes. Therefore, it can cover larger areas and volumes of air, as well as areas with higher ceilings. Siemens explains it like this: Their ASDs continually sample air from the monitored room using a connected pipe system with aspirating holes distributed along the length of the pipes. The air is drawn through these holes and into a detection chamber by an aspirator fan. It is then analyzed optically for the presence of smoke, using red and blue light (see Figure below).

A current example of the aspiration smoke detector comes from Siemens. In 2023 they have launched their new ASD+ that has two independent detection chambers in only one device and enables monitoring of rooms up to 6,700 m². According to Siemens, it is the largest area of coverage of any product currently on the market.

ASD+ is used in data centers, warehouses, road and rail tunnels, cable channels and other applications requiring very early detection, and where point detectors are hard to reach for service and maintenance. The ASD+ operates across a broad temperature range of - 20 to + 60 degrees Celsius, effectively functioning in both clean and harsh environmental conditions. Its versatility and robustness make it an ideal choice for diverse industries and demanding environments.

What Are Heat Detectors?

Simply said, this detector detects heat by having a way to measure temperature through voltage on a wire. There are two kinds of detectors that monitor changes in heat:

1. Thermal detector: This detector produces a temperature-dependent voltage through a wire. It detects changes in the temperature of that metal. Sensors can be platinum resistance or thermoelectrical thermometers. It is used in areas with sudden peaks of temperature.

2. Thermovelocimetric detector: It uses a thermistor to detect heat by connecting the deviation in temperature to the deviation in voltage. It is often used where no sudden changes in temperature are expected, such as car parks.

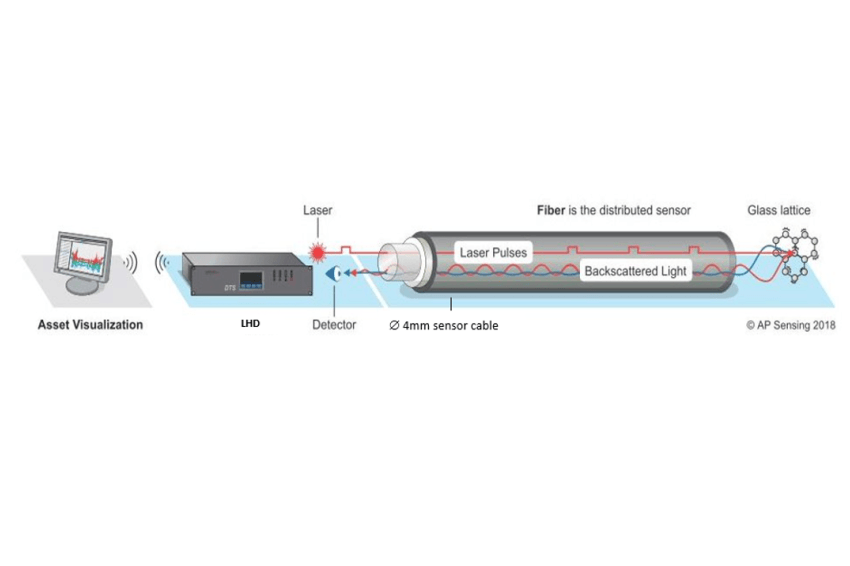

According to AP-Sensing, Fiber Optic Linear Heat Detection (FO LHD) technology offers fire and hotspot detection and monitoring in a wide variety of applications: protection of data centers, traffic and utility tunnels, car parks, conveyor belts, metro stations, refineries, warehouse facilities, and solar farms. With a passive fiber optic cable used as a distributed temperature sensor, the system measures thousands of temperature points in real time, monitoring photovoltaic system temperatures and detecting and locating hotspots within one meter.

What Are Flame Detectors?

Flame detectors are used to detect the presence of flames – as opposed to heat detectors that only detect temperature. There needs to be some sort of sensor that translates light. There are three kinds of flame detectors:

1. IR detector (Infrared): It detects infrared radiation emitted by flames through a photo diode and converts IR radiation into an electrical output signal through an emissive sensor element. This kind of detector is used in areas with a natural high temperature, such as highly combustible material or unattended machinery. So, there needs to be an instant response. The disadvantage is that it only works in case of a flame fire.

2. UV Detector (Ultraviolet): This detector uses a combination of light sensors, filters and photodetectors to detect ultraviolet light from flames. It is inevitable for areas with a high risk of explosion, such as chemical plants.

An application example for conveyor belts with highly combustible materials comes from Patol. Its 5000 series feature an infra-red transit heat sensor and the high temperature transit flame sensor. The sensor triggers at temperatures below the point of flaming, including both embers and buried hot spots, thereby providing the potential for intervention before flaming occurs.

What Is Thermal Imaging?

Thermal imaging functions similarly to the flame detector – except that the sensor translates heat and temperature into a thermal image by detecting infrared from fire. It even works on IR particles in the air or by absorbing sub-red light. The image that is created gives a visual expression of heat.

The fixed-mount thermal imaging cameras from Flir for condition monitoring and early fire detection are one product example. Flir A500f and A700f advanced smart sensor thermal cameras are ideal for users who want built-in, on-camera analytics and alarm capabilities for outdoor condition monitoring and early fire detection applications.

What Is Video Fire Detection?

A video fire detection system is basically an advanced video analytics software on a camera that can identify all sorts of ignition and fire indications as well as smoke patterns. The camera can detect the fire at its source in a matter of seconds. It is used in storage areas or areas with expensive and high-value machinery.

An example for a really advanced video fire detection system is another Bosch product: Aviotec currently uses more than 20 algorithms to analyze and detect the different ways that flames and smoke can present.

What Is a Gas Detector?

Gas detectors are used to detect gases that often come from combustible substances. They can detect toxic gases to give an alarm in the presence of explosive gas-air potential. It is most commonly used in industrial applications.

An example for an integrated gas detector is the latest member of the earlier mentioned Avenar 4000 family from Bosch. It is a smoke detector with an integrated CO gas sensor according to the new EN 54 regulations. As with the rest of the Avenar detector 4000 Series, FAP-425-Docto-R includes combined optical and thermal sensors but also an additional specialized sensor for rapid detection of carbon monoxide being a combustion gas that develops at an early stage of fire.

How High Can I Mount a Smoke Detector?

There is a reason why smoke detectors should be mounted within a certain ceiling level. It is simple thermodynamics: Warm air rises and so does smoke. The higher the smoke gets, the more it mixes with the surrounding air and it becomes diluted, colder and slower. When it cools down to room temperature it stops rising completely. At that point it doesn’t even get to the smoke detector early, although a fire may be in full swing.

The opposite is the case for regular air. Normally, warm air collects under the ceiling and forms a layer that is almost impenetrable for the smoke. For the smoke to rise even higher, it needs more energy, which must come from a larger, more established fire. This kind of air barrier is a problem for smoke detection. Of course, aspiration smoke detection can counteract the problem of higher ceilings a little bit but not completely.

As expected, Germany, the country of regulations, does state in section 6.1.5.3 of VDE 0833-2 a standard that regulates everything around fire detection and alarm systems. For example, there is a maximum ceiling height for smoke detectors that must not be exceeded. Optical smoke detectors should only be used up to a distance of 12 meters and a maximum of 16 meters if – and only if – their effectiveness can be proven.

What Is the Best Kind of Fire Detector at the Moment?

According to Jens Aperdannier, Team Leader Fire, Continental Europe, at Johnson Controls, this is not easy to answer – there is no one best solution as every system must be tailored to the customer’s facility and integrated with fire suppression systems where needed. Therefore, there is no “one-fits-all” detector.

He says: “Thanks to strict standards for fire detection systems, certified systems and components offer a very high level of reliability and functionality. The prerequisite is regular service and maintenance of the system by a certified installation company. In order for fire detection systems to function correctly, the design and commissioning phases are crucial. The design and commissioning of a fire detection system and its detectors depend very much on the customer’s building, the use of the rooms and the fire loads and materials in them.”

Aperdannier continues: “The most universal detector solution that is suitable for most applications is a combined detector which is able to detect smoke, heat and carbon monoxide. It measures all three fire characteristics independently and evaluates all three fire parameters by means of an algorithm to detect a possible alarm condition. In combination with a state-of-the-art fire panel, it allows a quick, reliable and highly parameterizable detection.”

How Can I Prevent Fires from Lithium-Ion Batteries?

With all the electrical cars and e-bikes on the market, people think about their batteries more. Detection is one thing, but in this case, it is even more important to prevent. So let’s take a look at this minor digression. According to Wagner Group, there is currently no ‘standard fire protection solution’ when storing lithium-ion batteries. The inherent potential of this form of energy storage to self-ignite cannot really be countered and, if there is a fire, conventional types of extinguishant are not sufficiently effective.

As you can read in the September issue’s cover story in full length, Wagner Group has the appropriate fire protection solutions in its portfolio to meet this requirement: Their OxyReduct fire prevention system. It gets into action before a fire has got a hold and thereby actively provides a high level of safety. Consequential damage, such as that caused by water, foam or other extinguishants, is prevented – and dangerous substances that can be released during a fire are also avoided.

Author: Lisa Holland

This is an article of our jubilee issue. Click on the button to find all of the interviews and the e-paper.

Contact

AP Sensing GmbH

Herrenberger Str. 130

71034 Boeblingen

Germany

*Flir Systems, Inc.

27700 SW Parkway Ave

97070 Wilsonville

OR

+1 503 498 3547

Johnson Controls

Am Schimmersfeld 5-7

40880 Ratingen

+49 21 02 71 41 0

+49 21 02 71 41 100

*Patol Ltd.

Archway House, Bath Road

RG7 5HR Padworth, Reading

United Kingdom

+441189701701